Wood Pellet Manufacturing Equipment

Posted by tubeicemachinesIf you have been looking for wood pellets machines, then you will be glad to know that wood pellet manufacturing equipmentis beneficial in processing wood waste such as straw or saw dust and this helps save money. At the moment, there are different equipment which are used for commercial and domestic production of wood pellets.

Generally, pellet equipment for homemade biomass pelleting are usually smaller and easily movable than the ones for commercial or industrial processing. Invariably, this also determines the size of the pellet that is produced. The ones for domestic use produce smaller pellet sizes from the raw wood while the ones for industrial purposes produce larger pellets. Anyway, the die can be adjusted to produce the desired size of pellets. Also, one can select a pellet mill depending on the kind of raw materials to be used.

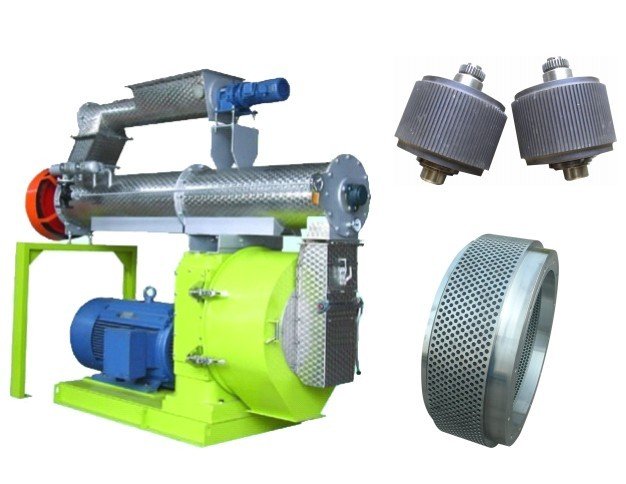

Although there are different kinds of wood pellet production equipment, generally, most of them have some main core components which can be noticed across the different brands. If you are searching for a pellet making equipment for commercial or domestic purposes, then you will find that most of the machines come with pelletizers, dryers, coolers, boilers, baggers, rollers, dies among other components. Anyway, there might be slight variations between the capacities of domestic and commercial wood pellet making equipment.

Most wood pellet manufacturing equipment can be adjusted to suit the production of desired pellet size. This means that one can adjust the diameter and the length of the pellets based on the size of the die. You should also know that different equipment have different pricing and in most cases, pricing goes hand in hand with capacity. The capacity may range from under 100kg/hour to a few hundreds of kilos. One can also ask for modification to specifications from the manufacturer to cater for special needs when making wood pellets.